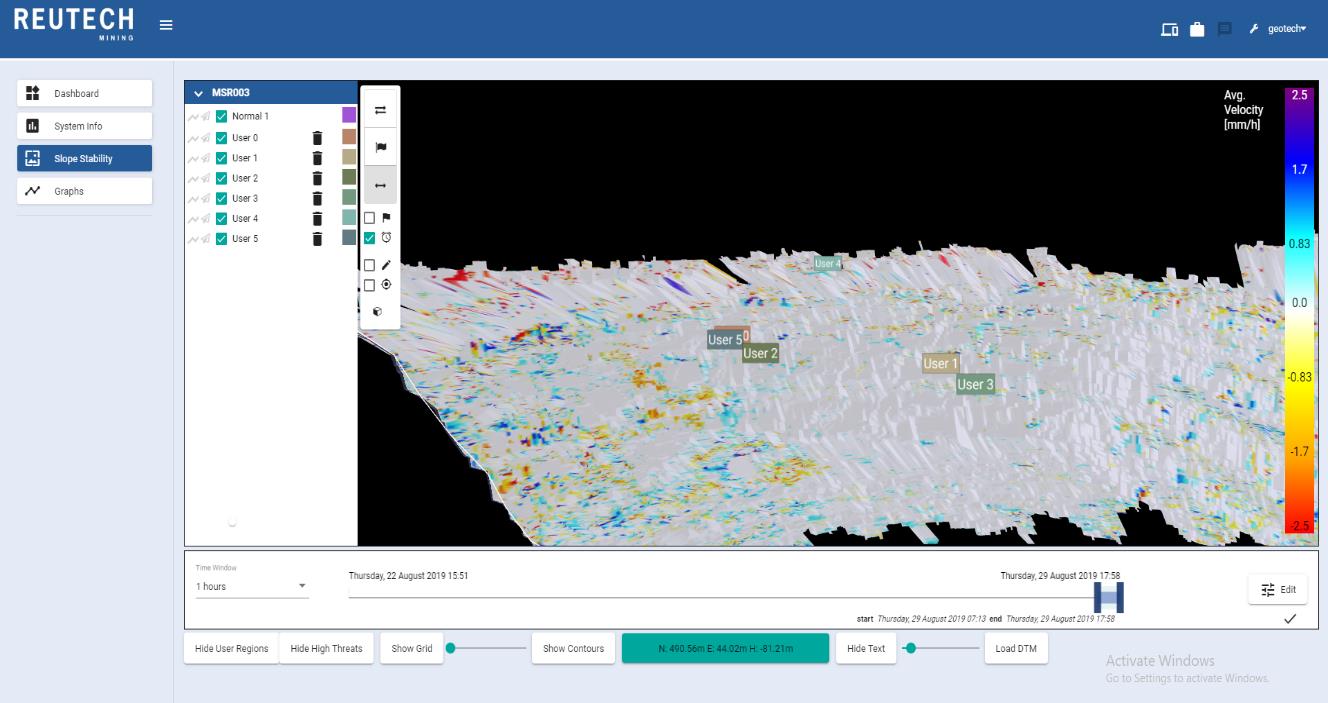

Mine Slope Stability Monitoring Radar System

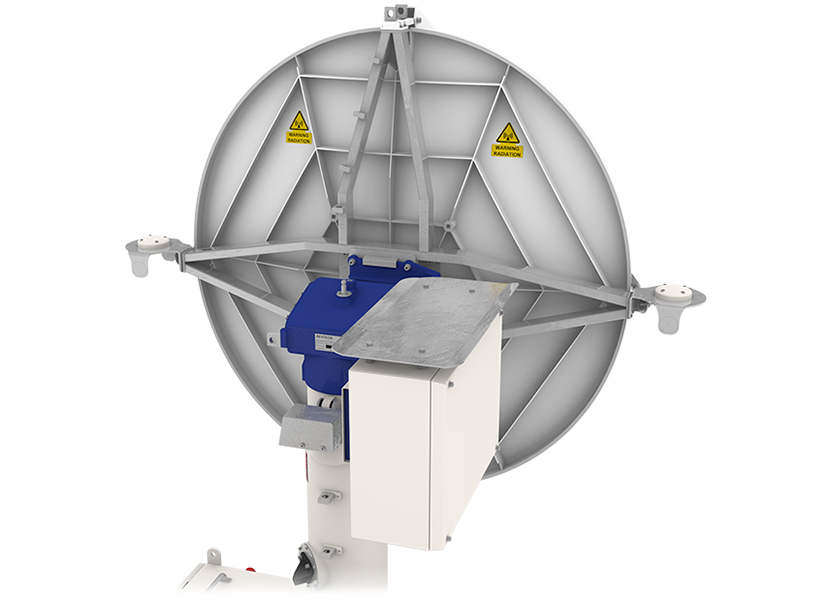

The Design

The Radar Module forms the foundation of the solution and can be supplied with electrical power to provide real time data at operating distances of up to 4000 meters. Intended to evolve with the requirements of operational and budgetary requirements, the MSR Modular allows for optional Battery, Generator and Solar Modules, all with a variety of mounting options.

Lifecycle costs are greatly reduced; with a new integrated power management system, drastically reducing the service requirements.

With a maximum scan speed of 40° per second, the MSR Modular covers broad areas in only a few minutes. The advanced parallel computing architecture processes data while actively scanning.

Lossless data compression algorithms combined with high speed wireless communication hardware provides instant remote access. This means that slope movement information and alarms are immediately available.

Anywhere. In real time.

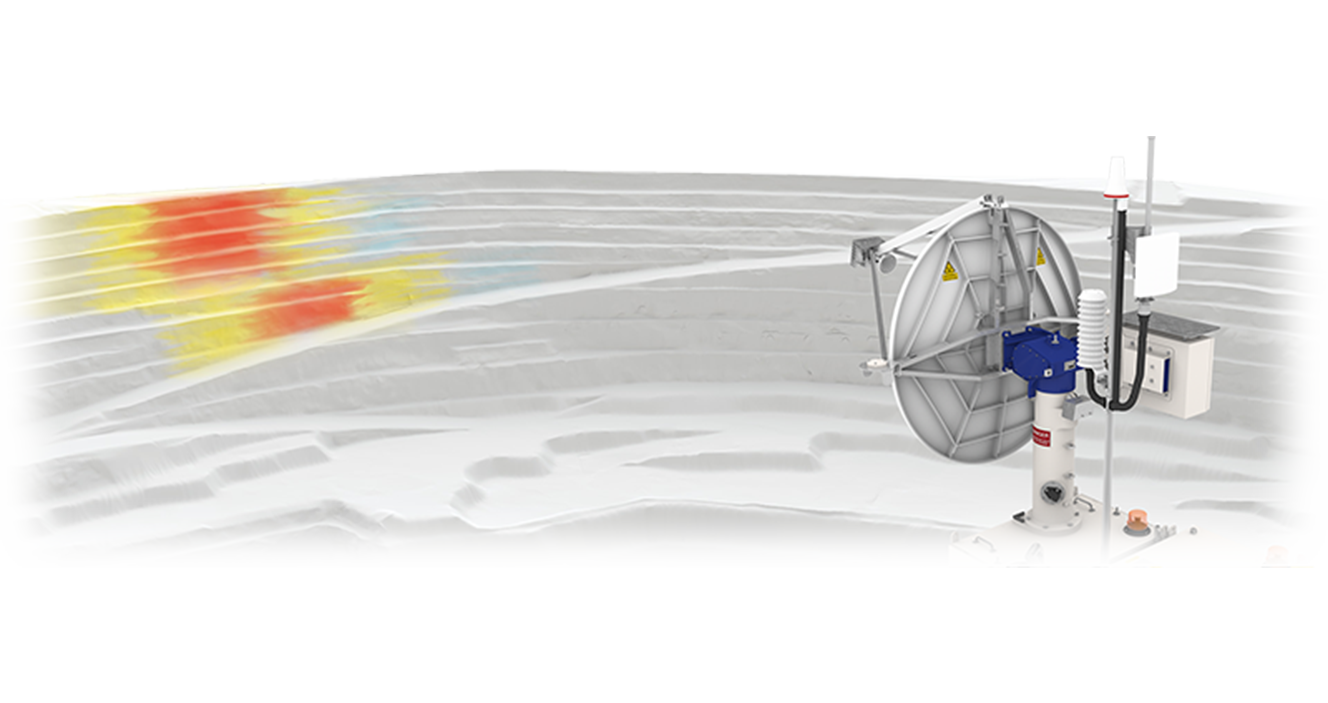

True 3D Data

Unique to Real Aperture Radar technology, the MSR Modular produces its own a high resolution true 3-Dimensional point cloud. Each point is individually resolved in range, azimuth and elevation to the highest degree of accuracy.

The result is smaller failure mechanism tracking, without relying on Digital Terrain Models or camera images.

Auto-georeferencing

The Integrated GPS with full GNSS capability now allows for quick and easy geo-referencing of the radar into the mine’s local coordinate system by the push of a button.

An Auto–georeferenced system can be deployed during the day or night and eliminates the requirement for line of sight to reference points on the mine when utilising a total station. Predetermined reference points can also be imported to determine the position of the radar within the local mine coordinate system. The hardware is a permanent installation that eliminates the need for additional tools or cables.

Exporting MSR Data

The MSR generates millions of 3-Dimensional surveyed data points. Each point is individually georeferenced and contains spatial and movement data which can be exported as a Digital Terrain Model or as a Comma Separated Value file.

That makes MSR data compatible with any third party mine planning and design software packages.

Integration

- Leica GeoMos

- Trimble 4D

- QuickSlope

- SlideMinder

- Rocscience

Environmental

With next generation atmospheric correction algorithms the need for Known Stable regions are eliminated. This means reliable radar data. Available when it’s needed most.

Standard temperature: -30°C to +55°C

Rain: up to 60mm/h

Low temperature kit: -50°C to +55°C

Relative humidity: 0% to 95%

Wind: up to 110 km/h

Dynamic Decision Making

The MSR, with optimized onboard signal processing and high speed wireless communication capabilities, delivers geotechnical data and alarming functionality in real time.

This translates to a comprehensive understanding of slope stability performance in an environment where dynamic decision making ensures improved safety and increased productivity.

Optimized Mine Design

Because the initial pit design contains a variety of unknowns, the back analysis of past failures becomes imperative. With the MSR’s advanced data handling and storage capabilities, 3-Dimensional georeferenced movement and surveying data can be exported to a variety of third party mine planning software packages.

This means that the slope design can be constantly optimised as new knowledge of the underlying mechanics at play is unearthed.

Geotechnical Monitoring Centre